Beverage filling systems

The leading manufacturer of high-performance filling & packaging lines | Global

Clear visibility for hygienic and reliable plant processes

Manufacturers of high-performance filling and packaging solutions for the beverage and food industries rely on LED2WORK luminaires across various machine and service areas. The objective is to ensure optimal visibility during operation, inspection, changeovers, and maintenance—even at high cycle rates and in 24/7 production environments.

Especially in hygiene-sensitive production environments, uniform, low-shadow illumination as well as a consistently robust and easy-to-clean design are essential. This is complemented by lighting concepts specifically designed for food & beverage applications, allowing flexible integration into different areas of the plant.

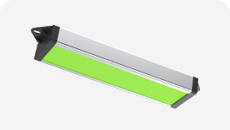

Product: INROLED 50 CleanPro

Application: Machine and system interior

Benefit: Safe visibility, hygienic process control

The INROLED 50 CleanPro was developed for demanding production environments where high protection ratings, regular cleaning procedures, and the use of process media are part of daily operations. Stainless steel components in media-contact areas, a high IP69K protection rating, and dedicated variants for food & beverage applications ensure reliable use even in sensitive zones. Certifications such as NSF and Ecolab support integration into hygiene-critical plant concepts.

Pharmaceutical filling systems

Pharmaceutical filling lines

Reliable lighting for validated and GMP-compliant processes

Manufacturers of pharmaceutical filling and packaging equipment rely on LED2WORK luminaires in sensitive production areas to ensure stable visibility along validated processes. Especially when filling liquids, injectables, or sensitive active ingredients, reproducible conditions, process reliability, and the highest hygiene standards are essential.

In pharmaceutical environments, in addition to uniform, low-shadow illumination, cleanability, particle minimization, and material resistance are of central importance. Particularly critical are media-contact stainless steel components, which enable safe, contamination-free cleaning and support GMP-compliant equipment concepts.

Product: INROLED 50 CleanPro

Application: Inside machines and systems in pharmaceutical filling lines

Benefit: Validation-safe visibility, maximum process and product safety

The INROLED 50 CleanPro was developed for demanding production environments where high ingress protection ratings, regular cleaning cycles, and strict hygiene requirements are standard. Media-contact stainless steel components, a high IP69K protection rating, and chemical-resistant materials ensure safe use in GMP-regulated zones. Certifications such as NSF and Ecolab support integration into validated cleaning processes.

Schmiede.one

Schmiede.one | Smart sorting with AI

Consistent lighting conditions for precise AI-based sorting

Schmiede.one develops innovative optical sorting machines for potatoes. Using vision systems and AI, potatoes are accurately classified by quality and size, while foreign objects such as stones or clods of soil are reliably detected and removed.

For stable and reproducible image evaluation, uniform and bright illumination in the camera area is essential—regardless of whether the machine is operated in a barn or directly in the field.

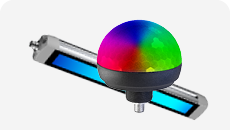

Product: FIELDLED EVO surface-mounted version

Application: Lighting in the camera area of sorting machines

Benefit: Stable image quality, precise AI detection, reliable process control

As the machines are used in mobile applications, ambient lighting conditions can vary significantly. The FIELDLED EVO delivers high light output to provide homogeneous, low-shadow illumination of the detection zone—even in direct sunlight or adverse weather conditions.

Thanks to its robust industrial design with an IP67 rating, the luminaire is well protected against dust, moisture, and mechanical stress. This ensures consistent lighting conditions, sustainably improving the quality of AI-based sorting and minimizing false detections.