Machine lights with signaling function

Robust LED machine lights with integrated signaling function – for status indication, safety, and optimal illumination directly on the machine.

LED signal lights are essential when machine and system statuses must be clearly and immediately recognizable.

LED2WORK offers a wide range of LED signal lights and hybrid luminaires: from precise RGB signaling to models with combined status indication and task lighting. Thanks to robust design and high-quality industrial components, our solutions are ideally suited for demanding environments – including CNC applications.

Robust LED machine lights with integrated signaling function – for status indication, safety, and optimal illumination directly on the machine.

LED system lights with signaling function – efficient illumination and color-coded status indication for industrial workstations and production lines.

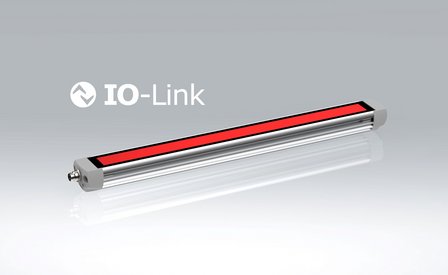

IO-Link lights for smart industrial lighting – directly controllable and ideal for networked production environments with high efficiency.

Signaling refers to the visual or acoustic communication of machine statuses – for example through color changes or audible signal sequences. It informs operators about operating conditions, faults, or maintenance requirements, thereby increasing transparency, efficiency, and safety in the production process.

In increasingly automated systems, fast and unambiguous feedback is essential. Clear light signals help detect faults at an early stage, prevent downtime, and shorten response times. This increases productivity and operational safety – especially in networked manufacturing cells.

IO-Link is an intelligent communication system at the sensor/actuator level that enables bidirectional data exchange between the controller and the light. This allows colors, flashing patterns, or brightness to be dynamically controlled, while status information from the light itself (such as temperature or operating hours) can be read out.

With IO-Link, complex signaling states can be defined digitally instead of using simple 24 V switching signals. Parameters such as color, intensity, and flashing frequency can be centrally managed, documented, and automatically adjusted when required. This simplifies integration, reduces wiring effort, and supports predictive maintenance.

In machine engineering, red, yellow, green, blue, and white are the standard colors – typically in accordance with DIN EN ISO 13850.

Red: Fault or hazard

Yellow: Warning or transitional state

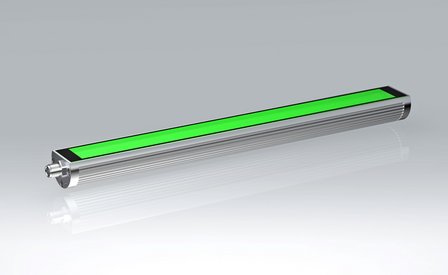

Green: Normal operation

Blue: Service or manual intervention

White: Neutral / status light

Yes – modern LED systems such as the DOMELED RGB-W IO-Link combine task lighting and signal lighting in a single fixture. They provide bright illumination of the work area while simultaneously signaling status changes through color shifts. This saves space and improves clarity.

Clear visual or acoustic signals warn employees of hazards, machine downtime, or ongoing processes. Distinct color coding helps effectively reduce errors, incorrect operation, and accidents—making a key contribution to workplace safety and process control.

IO-Link–compatible lights can be easily retrofitted using standardized M12 connectors. Existing systems benefit immediately from improved diagnostics, simplified wiring, and increased transparency.

Multicolor lights allow multiple machine states to be displayed using a single fixture. This saves space, reduces costs, and improves clarity. With IO-Link, colors, brightness levels, and flashing modes can be individually assigned—creating a clear and consistent visual language.

IO-Link transmits not only control signals but also diagnostic and status data. Operating hours, temperature, or malfunctions can be monitored in real time. This enables predictive maintenance, prevents failures, and optimizes the entire production process.

If you have individual questions or a specific request, we are happy to help.