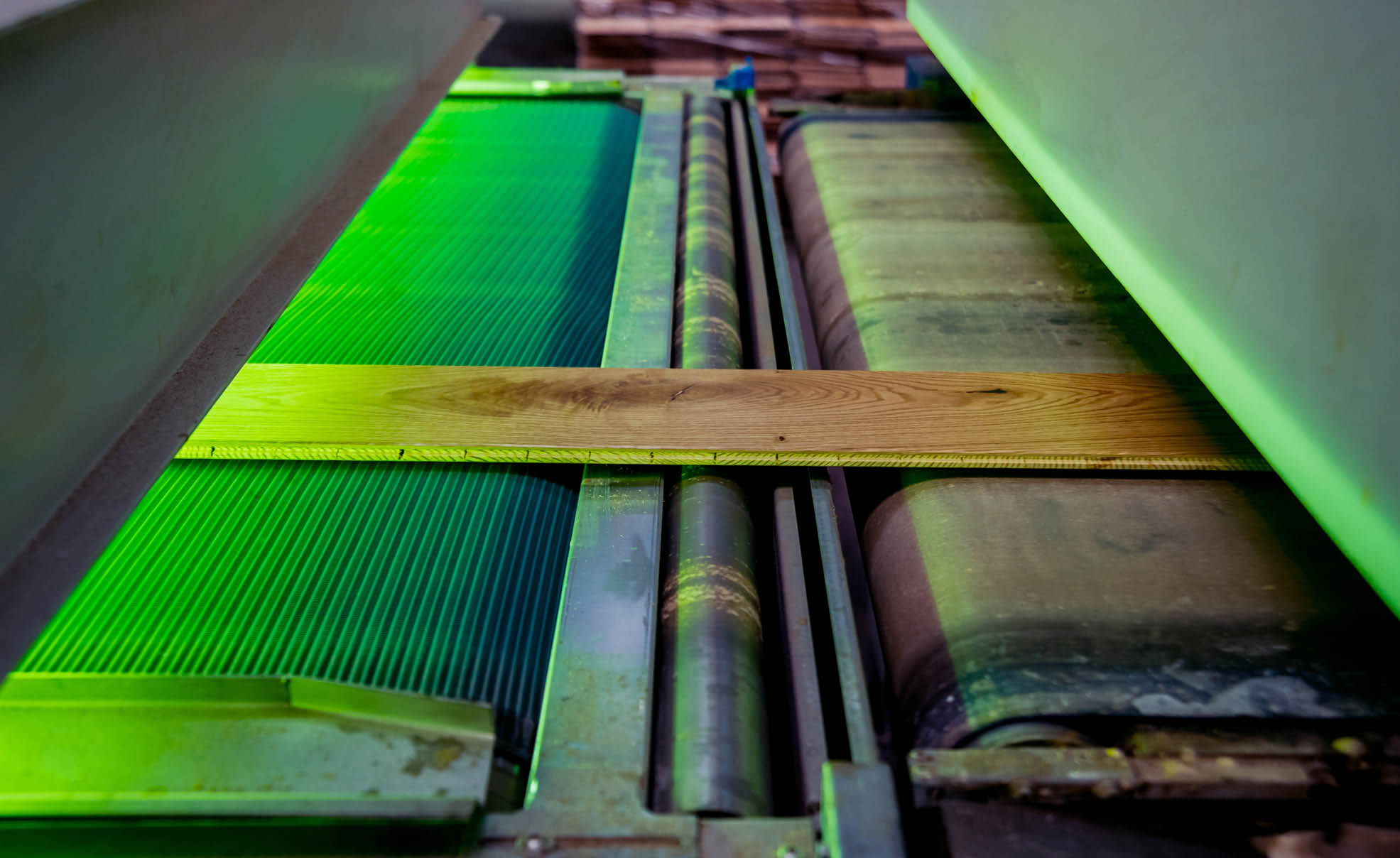

“Modern lighting and signaling solutions are now an integral part of PLC architectures. They create transparent processes, enhance machine safety, and form a central foundation for networked, automated production environments.”

- Holger Ritter CTO @ LED2WORK -

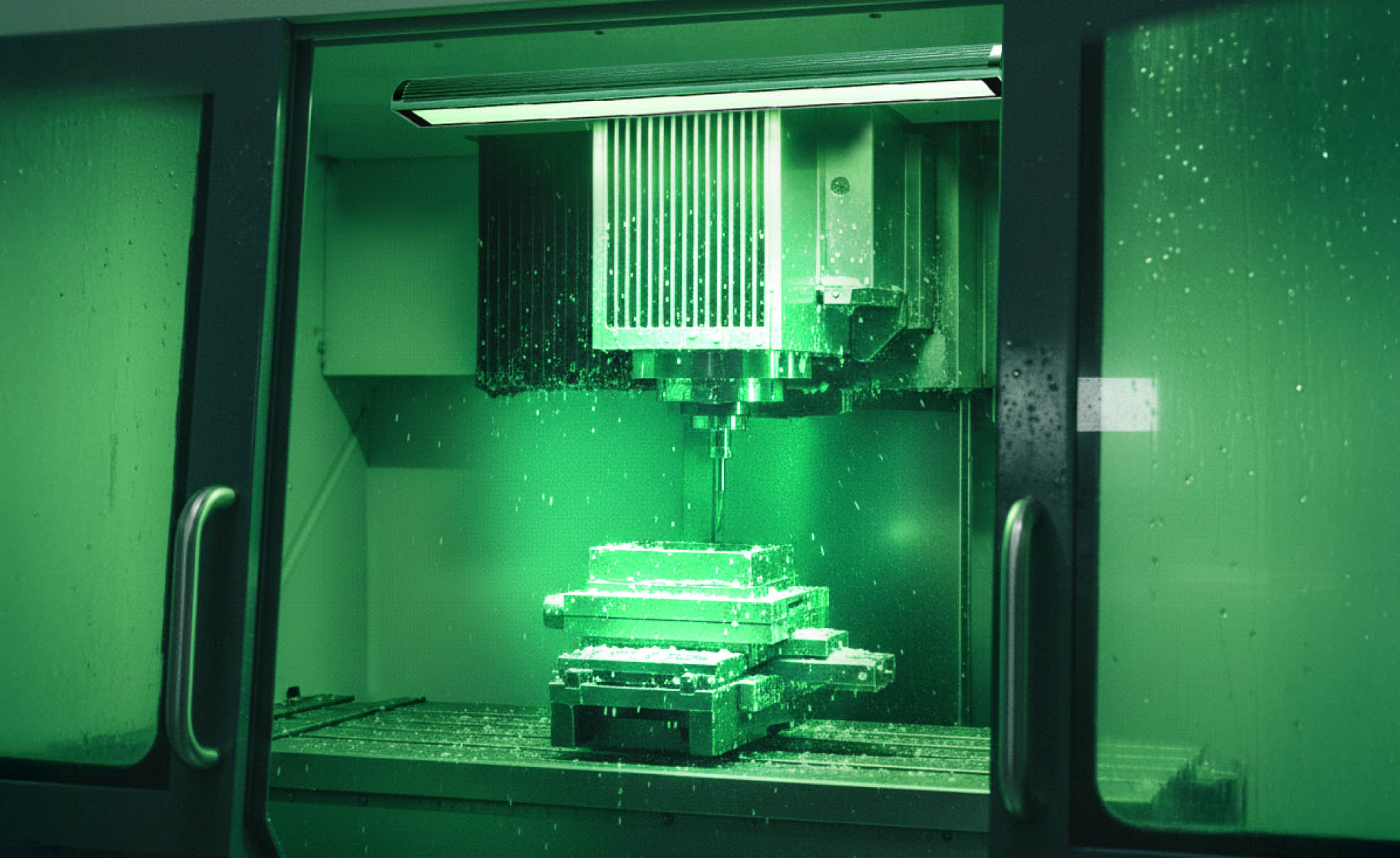

LED-Signaltechnik macht Prozesse sicherer und transparenter

Clearly recognizable signals & process reliability

LED signaling technology delivers instantly visible, unambiguous information—for operators, maintenance teams, and automation systems. This increases safety, improves response times, and reduces operating errors.

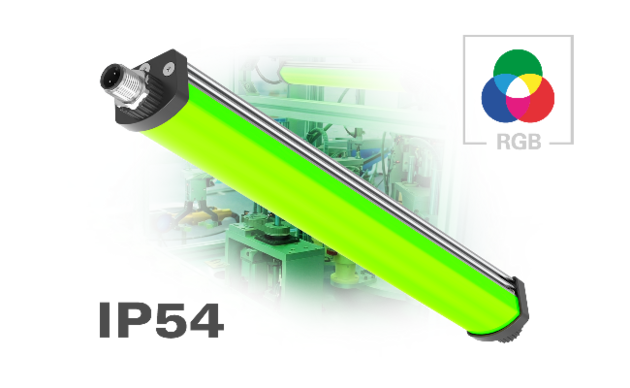

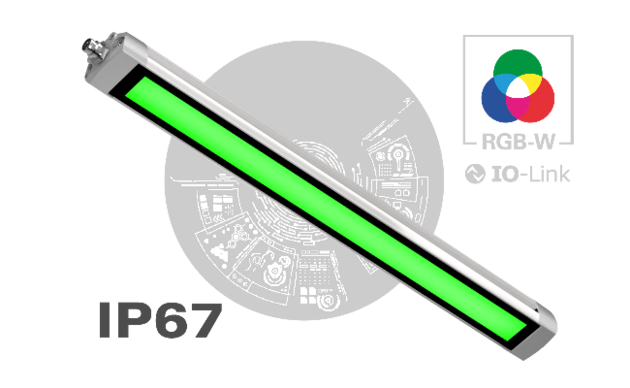

Industrial-grade & reliable in operation

LED signal lights from LED2WORK are robust, vibration-resistant, and designed for industrial environments. Even in 24/7 operations, signals remain stable, clearly visible, and highly reliable.

Efficient, flexible & future-ready

Modern LED signaling technology supports networked production processes with low energy consumption, long service life, and flexible control options. Ideal for machines, systems, and automated workflows.