Protection and Safety

Photobiological safety

The scope of the international standards on photobiological safety covers all electrically operated, incoherent broadband radiation sources, i.e. conventional light sources, which also include LED chips.

The relevant wavelength range extends from 200 nm to 3,000 nm, i.e. from ultraviolet to infrared. Our LED chips emit in the visible spectrum and therefore fall within the scope of DIN 62471, which defines exposure limits for optical radiation in terms of potential health risks and specifies the corresponding measurement methods. In this context, two types of retinal hazard are assessed: photochemical and thermal retinal damage.

DIN 62471 classifies luminaires and light sources into four risk groups:

- Class 0: Exempt group – no risk

- Class 1: Risk Group 1 – low risk

- Class 2: Risk Group 2 – moderate risk

- Class 3: Risk Group 3 – high risk

Our LED chips fall into the exempt group or Risk Group 1 and, in practice, remain well below the defined exposure limits in many respects.

Protection ratings

Our fixtures are protected against external influences such as dust, foreign objects, moisture, and water. Protection ratings are specified using IP codes, where IP stands for ingress protection. The protection levels are defined in the IEC 60529 standard and categorized into different classes.

For identifying a protection rating, the first digit refers to protection against the ingress of dust and solid foreign objects. The second digit indicates the level of protection against the ingress of water.

Protection rating coding

| First number | Protection against the ingress of dust and solid foreign objects |

| 0 | Not protected |

| 1 | Protection against solid objects with a diameter greater than 50 mm |

| 2 | Protection against solid objects with a diameter greater than 12.5 mm |

| 3 | Protection against solid objects with a diameter greater than 2.5 mm |

| 4 | Protection against solid objects with a diameter greater than 1 mm |

| 5 | Protected against dust in harmful quantities |

| 6 | Dust-tight |

| Second number | Protection against the ingress of water |

| 0 | Not protected |

| 1 | Protection against vertically dripping water |

| 2 | Protection against dripping water when tilted up to 15° |

| 3 | Protection against sprayed water at angles up to 60° |

| 4 | Protection against splashing water |

| 5 | Protection against water jets |

| 6 | Protection against powerful water jets |

| 7 | Protection against temporary immersion (max. 30 min at water depth = 1 m) |

| 8 | Protection against continuous immersion |

| 9K | Protection against very high-pressure water jets |

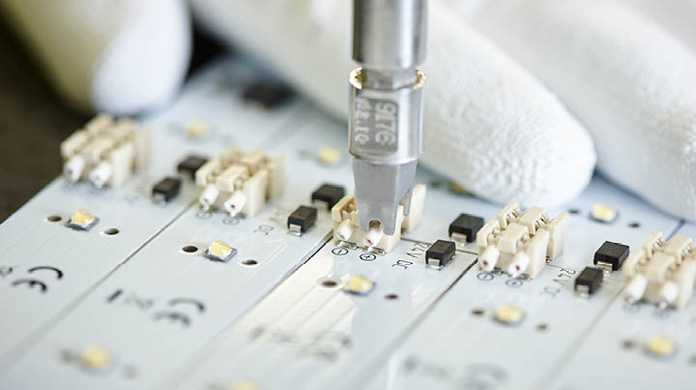

Protective circuitry

To safeguard against overvoltage and transient events, our fixtures are always equipped with protective circuitry integrated on the PCB. This additional circuit protects the luminaire from undesired failures caused by temporarily induced external signals and electrostatic transients.

In addition, every light source features reverse-polarity protection, which prevents damage to the fixture in case of briefly incorrect polarity (e.g., during installation or connection).

Protection classes

The designation of the protection class describes how hazards caused by electrical currents and voltages are reduced and prevented. The protection classes specify the safety measures implemented in the installation to prevent electric shock. Three approved protection classes are distinguished:

- Protection Class I applies to fixtures for which a protective earth connection is required.

- Protection Class II refers to enhanced insulation without a dedicated protective earth connection.

- Protection Class III is assigned to fixtures operated with safety extra-low voltage.