GROB-WERKE GmbH & Co. KG

GROB-WERKE | Plant & machine engineering | Global

Reliable lighting for demanding manufacturing processes

GROB-WERKE is an internationally active plant and machine engineering company with production sites in Europe, the Americas, and Asia. The company develops highly automated manufacturing solutions for automotive production, assembly technology, e-mobility, and universal machine engineering. GROB also relies on innovative technologies in the field of additive manufacturing.

In the GMP300 metal 3D printing system (Liquid Metal Printing), components are produced layer by layer under elevated ambient temperatures. Powerful, temperature-resistant lighting of the build chamber is essential for safe process monitoring.

Product: TUBELED_40 II RGB-W

Application: Build chamber lighting in metal 3D printing systems

Benefit: Temperature-resistant light, process visibility, signaling

A performance-optimized LED machine luminaire with RGB-W function is used. Thanks to sophisticated thermal management, the luminaire operates reliably at ambient temperatures of up to +70 °C (158 °F). In addition to homogeneous illumination with white light, the RGB function enables color-coded signaling of process states or production progress.

The luminaire belongs to the family of slim high-performance machine lights from LED2WORK with IP67/IP69K, safety glass, and high resistance to chips, oils, and coolants. This makes it ideal for use in harsh production environments and enclosed machine spaces.

GDW Werkzeugmaschinen GmbH

GDW machine tools | Precision lathes

Optimal visibility for manual and automated turning processes

GDW Werkzeugmaschinen GmbH develops and manufactures high-quality precision lathes – ranging from conventional hand-lever machines to CNC-controlled turret lathes. The modular product ranges allow application-specific customization to meet individual customer requirements.

As many work steps – from setup to changeover – are carried out manually, reliable and high-performance lighting directly in the working area is essential. To optimally illuminate the area between the chuck and spindle, GDW relies on LED machine luminaires from LED2WORK.

Product: TUBELED_40 II ECO

Application: Working area lighting in lathes

Benefit: Clear visibility, high process reliability, long-lasting lighting

The LED machine luminaires used impress with their robust design featuring IP67/IP69K, high resistance to coolants, lubricants, and chip impact. Daylight-white area lighting ensures high-contrast, low-shadow illumination of the working area. Thanks to light-forming technology and opal glare control beneath safety glass, the light is evenly distributed.

The luminaires are vibration- and shock-resistant, can be mounted flexibly, and are powered directly via the machine supply. Modern LED chips provide high light output with low power consumption and reduced heat generation. In addition, the luminaire offers an ON/OFF interface for load-free switching, flashing, and dimming – ideal for future digital machine concepts.

OTEC Oberflächentechnik GmbH

OTEC Precision Finishing | Surface finishing machinery

High-contrast lighting for perfect surface quality

OTEC Precision Finishing develops and manufactures machines for deburring, grinding, smoothing, and polishing. The systems are used worldwide in the automotive, medical, electrical, toolmaking, and mechanical engineering industries, as well as in the watch and jewelry sectors. At its Straubenhardt site, highly precise solutions for processing metal, ceramics, and plastics are produced.

For almost ten years, OTEC has consistently relied on LED lighting from LED2WORK when equipping its machines. The goal is detailed, high-contrast illumination of all relevant work and process areas—from assembly through to final finishing.

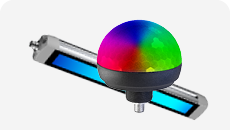

Product: LEANLED II, TUBELED_40 II POWER, TUBELED_40 II RGB-W

Application: Lighting in grinding, polishing, and deburring systems

Benefit: Precise visibility, rugged industrial lighting, visual process signaling

Depending on the application, the LED2WORK machine luminaires used cover protection ratings from IP54 to IP67/IP69K, making them suitable for both dry machines and harsh production environments. Daylight-white area lighting ensures uniform, low-shadow illumination. Modern LED chips deliver high lumen output with low power consumption.

RGB-W luminaires are used in setup and loading areas. These enable color-coded signaling of process states—an ideal space-saving alternative to traditional signal towers. The luminaires are vibration- and shock-resistant, protected against chip impact, and designed for elevated ambient temperatures of up to +70 °C (158 °F). In addition, ON/OFF interfaces for switching, flashing, and dimming are available—prepared for future digital machine concepts.

Kardex Remstar

Kardex Remstar | Automated storage systems

Precise lighting for efficient order-picking processes

Kardex Remstar designs and delivers automated storage systems to optimize warehousing and material flow processes. As part of the globally operating Kardex Group, the company stands for efficient intralogistics solutions that make optimal use of available space and consistently automate manual processes.

At the Neuburg an der Kammel site, customized systems are produced for the German market, including the Vertical Buffer Module – a scalable, fully automated storage concept for bins and trays. The systems are software-controlled and enable precise storage and retrieval in both horizontal and vertical directions.

Product: TUBELED_40 II POWER, LEANLED II

Application: Lighting for picking and retrieval areas

Benefit: Safe picking, error-free order fulfillment, ergonomic visibility

The LED2WORK luminaire is integrated into the cantilever above the rotary table and provides targeted illumination of the access area. Switching on and off is conveniently controlled via the system’s control panel. Despite its compact design, the luminaire delivers high lumen output—ideal for confined installation spaces in automated systems.

Thanks to modern LED technology, the luminaire provides flicker-free 100° area lighting, is vibration- and shock-resistant, and free from UV and IR components. An ON/OFF interface enables load-free switching; flashing and dimming are also possible. Integration is achieved via standard connectors commonly used in automation technology—perfectly matched to networked storage systems.