DOMELED IO-Link

LED signal light with 360° visibility for clearly visible status indication, even in confined spaces

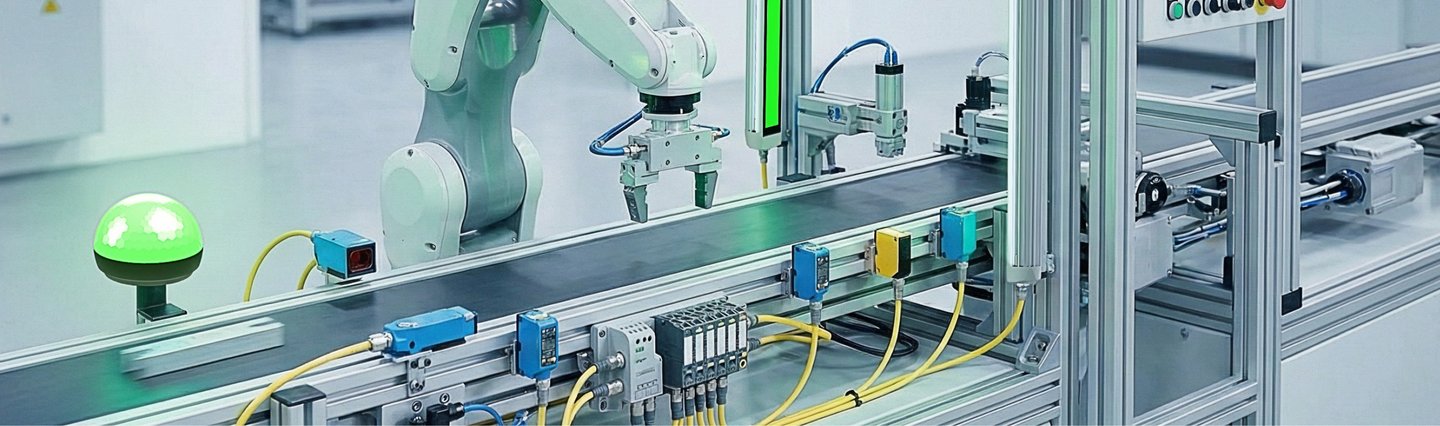

IO-Link is a manufacturer-independent communication technology for connecting sensors and actuators to higher-level control systems in automation.

IO-Link enables bidirectional communication between devices at the lower field level—such as sensors and actuators in automation—and higher-level control systems like a programmable logic controller (PLC).

IO-Link was developed to overcome the weaknesses of fieldbus installations or parallel installations used to control sensors and actuators in automated systems.

The integrated IO-Link board enables intelligent control of the LED2WORK LED luminaire. This allows adjustment of brightness, switching from white light to signal colors, RGB color changes, flashing frequency, and the configuration of additional parameters.

Configuration and control of lighting and signals are handled via the higher-level control system, increasing the system’s flexibility and adaptability. The system does not have to be a fully automated plant. Controllers of machine tools or similar equipment are also suitable, provided the IO-Link master is compatible—that is, it speaks the same language.

With the extensive diagnostic capabilities, potential issues or failures can be diagnosed in real time, significantly simplifying maintenance and troubleshooting compared to conventional systems.

The IO-Link capability allows the parameters of LED2WORK LED luminaires to be adjusted during ongoing operation, enabling quick adaptation to changing requirements. Replacing LED luminaires during an active process is also easily possible.

LED2WORK IO-Link-enabled LED lights can be implemented using standard connectors and cabling systems, reducing wiring effort. The minimum requirement is a simple three-wire sensor cable. Bidirectional communication takes place via the same cable that also provides the power supply.

LED2WORK IO-Link-enabled LED luminaires offer a high degree of system flexibility and scalability. The number of connected luminaires can be easily reduced or expanded without requiring major changes to wiring or configuration.

LED2WORK LED luminaires are inherently very energy efficient. Through precise control of the IO-Link-enabled LED luminaires, efficiency can be further increased, as brightness and operating status can be adjusted exactly to demand.

The integration of LED2WORK IO-Link-enabled LED luminaires is an intelligent, flexible, and efficient solution for lighting and signaling in automated environments.

To carry out an installation and operate our IO-Link-enabled LED luminaires, at least the following components are required:

This refers to LED luminaires such as the TUBELED_25 RGB-W IO-Link and upcoming LED luminaires from LED2WORK that support the IO-Link communication standard.

When the LED luminaire is integrated into an IO-Link installation, it becomes an actuator. The LED luminaire can then transmit various parameters via the IO-Link protocol and, in return, execute commands from the control system.

The IO-Link master is the interface between the IO-Link-enabled LED luminaire and the higher-level control system.

The IO-Link master acts as a kind of interpreter, translating and enabling communication between the connected LED luminaire on one side and the control system on the other.

IO-Link masters are equipped with one or more ports for IO-Link devices. If the number of ports is insufficient, an IO-Link hub can be connected to provide additional ports.

Connection cables are required to link the IO-Link-enabled LED luminaire to the IO-Link master. The cables and attached connectors must meet the requirements for transmitting digital signals and power.

For connecting the IO-Link-enabled LED luminaire to the IO-Link master, the minimum requirement is a three-core sensor cable, which as a guideline should not exceed 20 m (approx. 66 ft) per connected device.

The connection from the IO-Link master to the control system, however, must be adapted to the specific conditions in order to ensure reliable communication via fieldbus, TCP/IP, or another communication protocol specified by the control system.

Both the IO-Link-enabled LED luminaire and the IO-Link master require a power supply.

As a rule, the IO-Link master is connected to the standard 24 V DC supply voltage commonly used in industrial automation. The LED luminaire is then powered directly by the IO-Link master.

To process the information from IO-Link devices and execute control tasks, a higher-level control system—such as a programmable logic controller (PLC) or a distributed control system (DCS)—is required. This is also where parameterization of the connected IO-Link devices takes place.

An IO-Link configuration tool is required to configure the IO-Link master at the control level and to parameterize the connected LED luminaire.

This tool can be hardware- or software-based and is usually included in the scope of delivery of the IO-Link master.

Newer control systems that are already designated as IO-Link-capable may provide integrated configuration tools for IO-Link applications.

For safe installation, both the LED luminaire and the IO-Link master require suitable infrastructure such as cable trays and mounting fixtures.

“Those who understand but do not act have not truly understood.” Wang Yangming